As of July 2024, Kyra tent is only available in Spicy Orange colors. Yellow color will be available in August 2024.

Two-person, single-wall, all-season dome tent.

Kyra 2 at 1630gms trail weight is a lightweight tent solution for alpinism, backpacking, cycle touring and other such uses where going lightweight is critical.

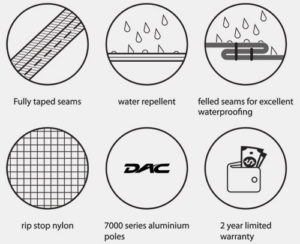

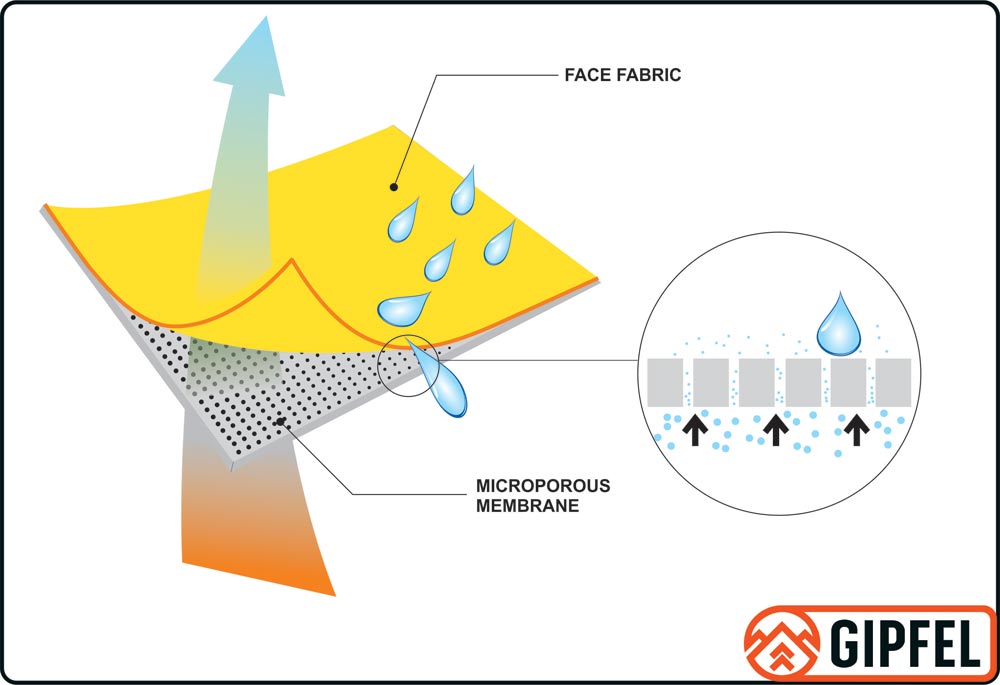

World class materials, and a design tested and proven in Himalayas, has this tent receiving rave reviews from all over. Thanks to a water resistant and breathable laminated to the canopy fabric, the condensation has been minimized. This tent has been tested thrice in Himalaya with an aim to achieve minimum condensation. One of those three times was on slopes of Mt. Makalu (8,485 m) in Nepal.

Canopy and poles are packed separately, and can be cinched together if needed; for flexibility of packing.