A major factor in purchase of anything is the durability of the product. All outdoor products have a lifespan. At Gipfel, our endeavour is to make quality products that will last long, and do not add to the pile up of garbage and increase our environmental footprint.

In that spirit, how long do the tents last?

There is really no short answer to this!

A good analogy for a tent of any quality, is cars. Consider this, if you do not put a lot of mileage on your car, and if you take care of it, the car will stay pristine for a long time, and then there is correlation between the initial build quality, use, and maintenance, and longevity.

But we do not make Gipfel tents hoping they will sit on the shelf. We make our tents in anticipation that they will be put through the worst weather there is.

Firstly, the life span will vary considerably basis use. Tents bought for personal use will last much longer than the same tent that will be used by a commercial tour operator or a tent bought for collective use by clubs, etc.

With good care and maintenance, a Gipfel tent will last you between three to eight years with frequent use.

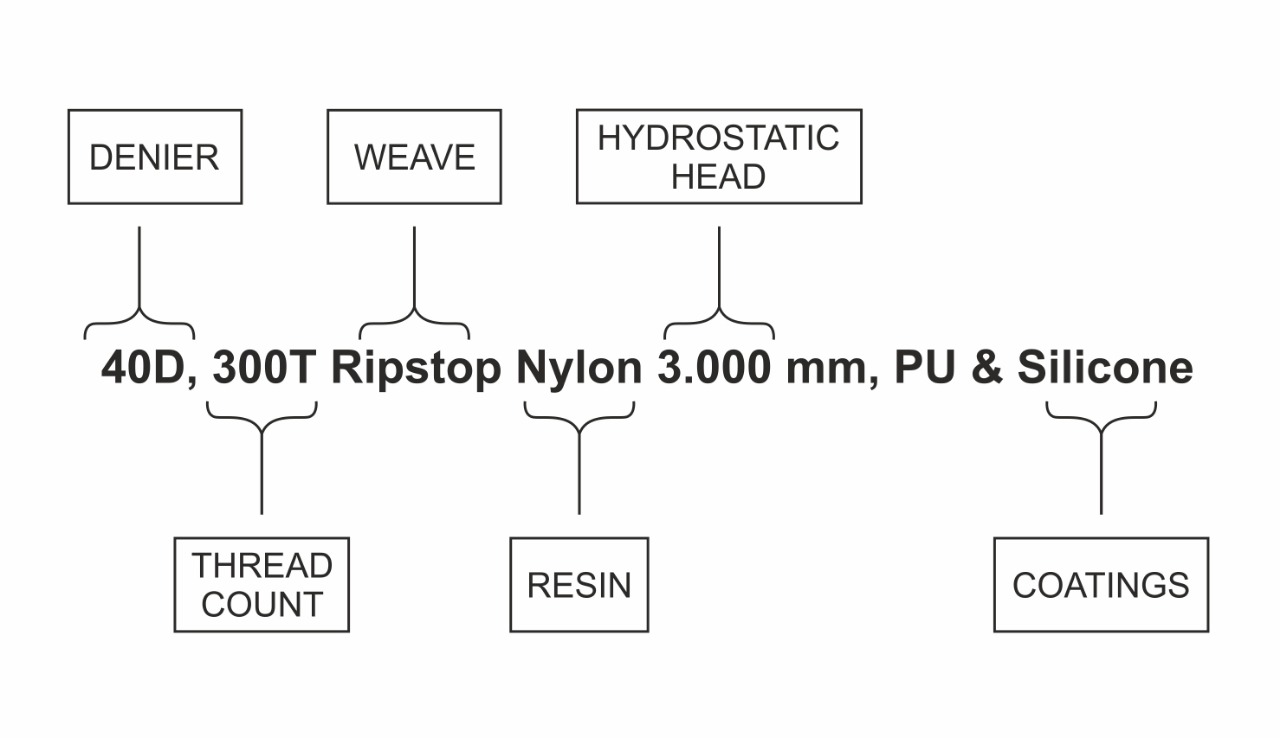

The basic longevity comes from the quality of materials, coatings and manufacturing.

Factors that will determine the life span of your tent

-

Build quality and Materials

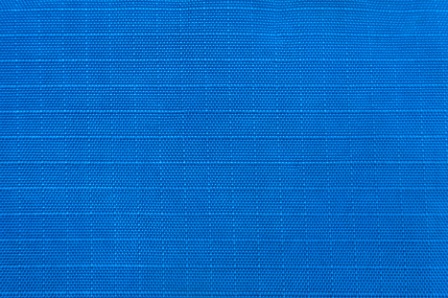

If you want a durable and a quality tent, that functions as it should in the inclement weather, start with a tent that uses high quality components, and focuses on manufacturing quality controls.

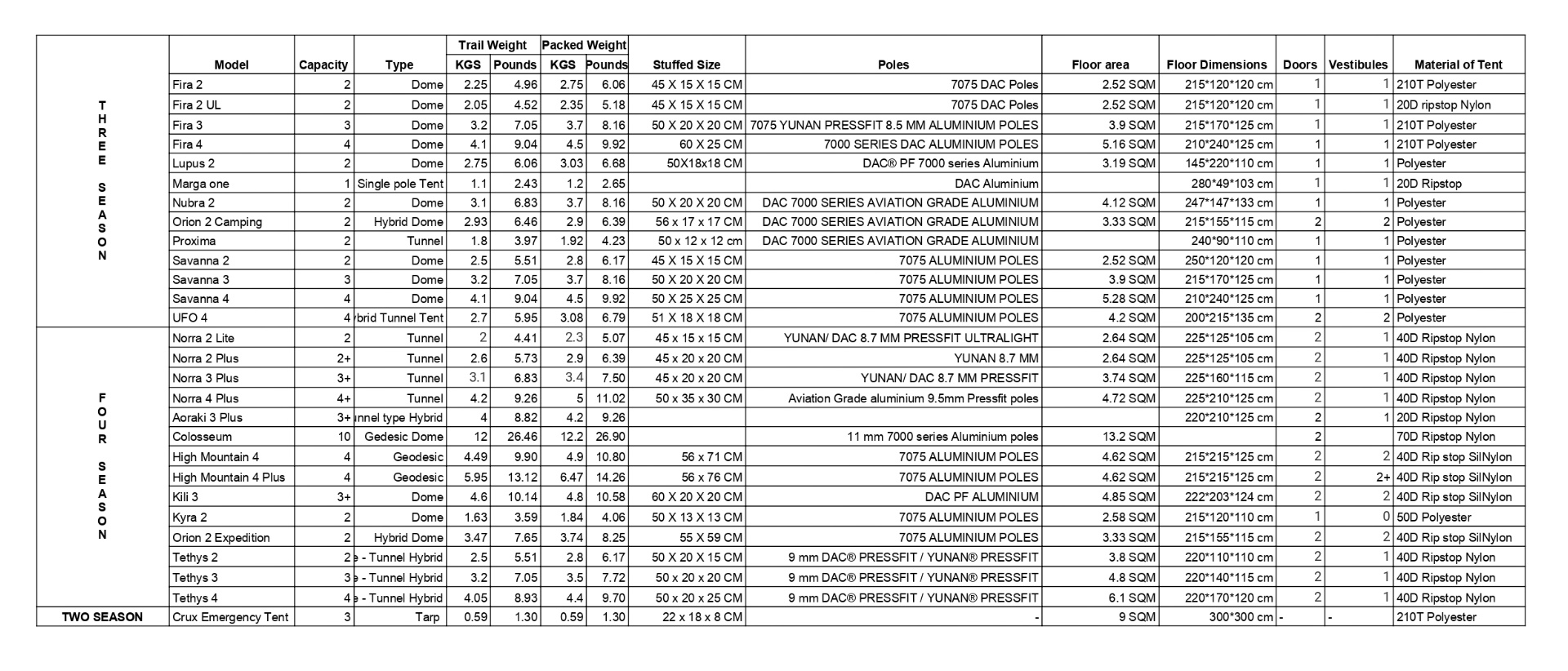

At Gipfel, we choose world class components whether it is the poles (all our top end models use DAC or Yunan poles), the fabrics, or accessories like the zips (we use only YKK zippers). Our processes ensure qualitative build of the tent.

Even amongst good quality tents, some tents last longer than others.

Some tents are built for endurance and will last a decade, some focus on use in extreme conditions and should be replaced or repaired every couple of seasons with extreme use.

A car camping tent typically will last longer than a tent bought for high-altitude expeditions. While car camping, you will handle your packed tent a lot less, and the typical weather it is pitched in is lot less severe, than say the high altitudes, where the rain, snow, and importantly the UV radiation is much higher.

To give you a reference point, we anticipate a Gipfel Norra 3 tent will last for 5 years if it is used 50-60 days, at an altitude of 3,500 – 4,000 meters. The lower these numbers, the greater will be the life span.

So, does that mean we anticipate 250-300 days of use from a tent such as Norra 3. If being used continuously within a year, we expect the use-days to be higher, because the age-based degradation wouldn’t have set in as yet.

If you think about it, that is a bold assertion from our end. UV exposed tents have known to start degrading within a month of being pitched.

-

Frequency of use and altitudes

The more frequently you use your tent, the faster it will wear down because of UV exposure. The same applies to the altitude.

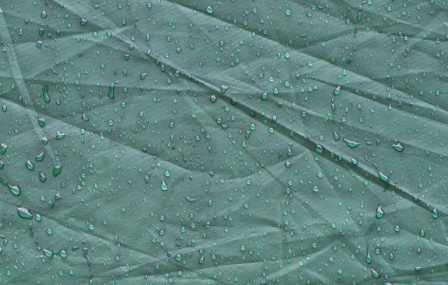

Prolonged UV-exposure wears down the tensile and tear strength of the textile. It also deteriorates the coatings on the textile.

This is when you take care of the tent properly and follow the tips given below.

Note: We infuse UV stabilizers in our textiles for 4- season tents to retard degradation.

The Accelerated Weathering – UV exposure chamber test help us determine the impact on these changes to UV exposures. The amount of UV rays a textile will be subjected to in say 6 months at a 3,500 meters altitude above sea level, the chamber can produce that in just 2 days of testing. After the exposure, we test the tear strength again to check the impact.

-

Storage

Always dry your tent before packing in, especially for long term storage. Ensure all the moisture is removed. In the short haul, and while on expeditions, this might be difficult to do.

The biggest enemy of a tent is the mold. Everything else is reparable, but not the mold.

Once the tent catches mold, you will have to discard it. The textile cannot even be cut and used to make something else. You know that the tent is moldy, if it releases a string musty smell. Also, you will see small brown spots forming on the textile that may be removed temporarily after wiping but it will return. The PU coating will also peel off rendering the tent less water resistant.

Have you ever been in a tent that had that sharp musty smell that reminds you that the tent might be pretty old, that is the smell of PU. Someone has not been listening and been packing the tent damp!

Every Gipfel tent has an instruction sewn inside the inner tent pocket that reads as following.

Roll the tent for packing. Do NOT stuff the tent. Repeated creasing and folding will eventually damage the waterproofness of the tent.

-

Pitching: Watch for the Failure modes and Prevention

Poles:

Gipfel tent poles are made of highest grade of Aviation Aluminium (7000 series) AND they should last a lifetime. However, this is one of the single biggest failure-point of the tents in the field, especially with our Commercial Operator customer base.

These pole segments are joined with the help of inserts between the poles.

If the poles are not properly joined, and the insert tubes are visible, the poles may snap.

We provide a repair tube with every tent. Click here to check out how to use a repair tube. The same applies when you take them apart.

We do provide the service of replacing the snapped pole segments, and the poles could be repaired at home with stretch cord, and we find this to be the single most damaged element of the tents. Our valuable commercial operator customers reach out to us to replace 100s of these poles every year. And all it takes is a bit of sensible care to ensure you have a fully functioning tent in the field.

Zippers:

The YKK Zippers we use in our tents are heavy duty and are rated to work efficiently even at -60 degrees Celsius.

And they should last the lifetime of the tent. However a busted tent zipper is the most annoying thing you could have, after the poles snapping, and fabric tears.

However, just take care of the small things like keeping them clean of dirt and grit, not to brute-force the zipper when it gets stuck in the fabric (work it gently to remove the snag), and use zipper lubes periodically after every season to keep them working smoothly.

Fabrics:

The tents we make are absolute beasts in handling inclement weathers. But these beasts still need tender loving care.

Do not walk in your tent with your crampons or ice cleats on! This is the single biggest issue we see with the tents that come back for repairs from our customers. (We offer replacement inners and outers, and foot prints.)

To extend the life of the fabrics and the tent overall:

- Use tent foot print or ground sheet underneath your tent, when you can.

- Protect your tent from UV, when you can and as you can.

- Keep the insides and outsides clean of dirt and grit.

- Do not machine wash your tent, If washing, set up your tent, and sponge it down with a non-detergent mild wash, and dry it out completely in shade preferably.

- Re-waterproof your tent as per recommendations below, use a seam sealant available (Coghlan’s Seam Seal is available locally).

Where to Pitch:

Take time to clean your camp site. Sharp stones and roots poking out of the ground will damage the tent.

As mentioned above, UV damage is real and can degrade and destroy the fabrics over a period of time. So, pitch accordingly.

-

Is there any spray to replenish the waterproofing of an old tent?

Waterproofing (water resistance)? No!

Water-repellence /DWR? Yes!

The waterproofing (water resistance is a more appropriate term) comes from the PU coating on the inner side of the outer rainfly.

Anything coated on outside like DWR or Silicone, like in case of Gipfel tents – Silicone, only makes it water water repellent and not water-resistant.

The water repellence only helps in keeping the textile from absorbing water and stretching and sagging. It also offers the dye and textile some fastness to UV rays.

This water repellence lasts only few months with frequent use, so there is spray-on stuff available in the market that replenishes the water repellence, but that’s it.

This outer coating alone cannot make the tent water resistant. The inner coating is what will give water resistance. Unfortunately, once the inner coating comes off, there is little you can do because it cannot be sprayed on.

Here are some tips on proper tent usage and minor repairs. Click here