In this series we will try to demystify the components that go into making tents.

What is a good balance between weight and the durability, weight and the degree of waterproofing? What fabrics are suited for what terrain?

Having spent years designing and producing tents, right from the conceptualization through schematic drawings, pattern makings, prototyping and then bulk production, there is a reasonable amount of knowledge we have accumulated about camping tents.

All Gipfel tents are produced in our own factory located near New Delhi (India), and the components are sourced from the best in the world.

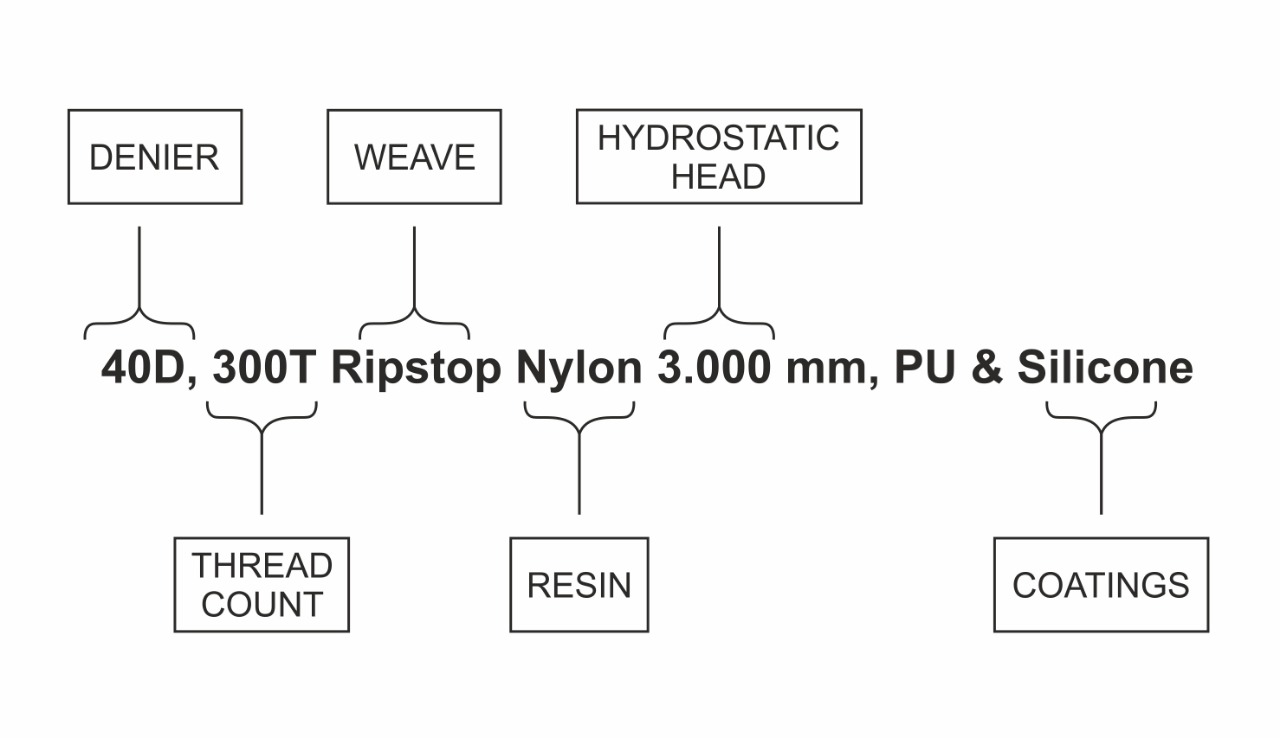

To explain the textile used in tents, let’s see how you normally come across the textile description used by various tent makers. All of us mostly use a similar format.

DENIER (D)

This is the measure of the thickness/density of the synthetic yarn of the woven textile. The higher the denier, the thicker and heavier the yarn is. A higher number also means that the textile is probably stronger.

For example, a 20D Nylon is lighter but weaker than a 40D Nylon. Also important to note is that, lower denier also means less tensile strength and faster degradation in sun. So in the higher altitudes, a 40D or 70D would be better. Beyond 70D, the fabric will be stronger, but the weight penalty will begin to kick in.

Taking a closer look, literally; if you look closely at the tent textile, the yarns are woven at an angle of 90° to each other. The horizontally arranged yarns represent WARP and the vertically arranged yarns represent WEFT. The denier values are represented in this format Warp (D) x Weft (D). Mostly the same yarn is used in both sides. However, if you see something like this 40D x 70D, then it means that the textile has Warp of 40 Denier and Weft of 70 Denier.

THREAD COUNT (T)

It represents the total number of yarns in Warp and Weft directions in a square inch area of textile. With higher the thread count, textile will the thinner, lighter and suppler. Basically, it has a better hand feel.

A higher thread count is great for sleeping bags but not always great for tents. For example, a 210T Polyester is stronger than a 300T Polyester. We use 210T Polyester for tents used by commercial operators. They are heavier but more durable. However we prefer to use 300T textile for sleeping bags. The hand feel is great in this thread count.

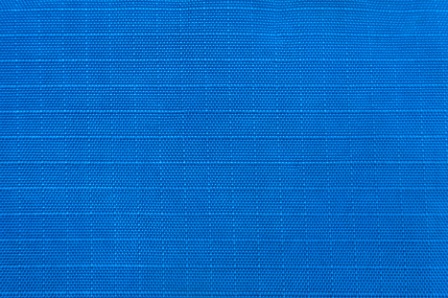

WEAVE TYPE (RIPSTOP OR PLAIN WEAVE)

There are many types of weaves in textiles, but in tents we mostly use Rip stop or Plain Weave taffeta. As the name suggests, rip stop textile is a type of fabric that is incredibly resistant to rips and tears. A grid is woven into the face fabric to prevent small rips and tears from spreading and completely destroying the entire piece of fabric. This mesh is easily visible if you look closely. The mesh looks like a square or a diamond. These patterns can be small or big.

For example, Gipfel Fira 2 UL tent has 1mm rip stop (side of square is 1mm long). The Gipfel High Mountain tent has a 5 mm rip stop. Plain weave has no mesh. A rip can spread out much more easily in this textile, especially if it is a light weight textile.

RESIN TYPE

The tent textiles for light weight camping tents are largely synthetic materials, i.e. plastics. The textile is woven from yarns and the yarns are made from plastic resin. The most commonly used ones in tents are Nylon and Polyester.

Nylon is amazing. It has higher strength to weight ratio than Polyester but less so than speciality fibers like the Dyneema. Unfortunately, Nylons absorb water and expand making the tent loose. The tents made from Nylon require frequent re-tensioning of guy lines depending on the weather and what time of the day it is. Additionally, the color fastness to UV exposure in Nylon isn’t as great as Polyester.

Despite the cons, Nylon is still the preferred textile for high specification tents because Nylon is stronger and lighter. A 70D Nylon is lighter than a 68D Polyester. As far as the cons are concerned, there are ways to minimize the effect of disadvantages as will be explained in the COATINGS section below. UV stabilizers are added to the textile for better color fastness in the Gipfel tents.

WATER RESISTANCE (HYDROSTATIC HEAD)

This is the measure of the amount of water that the fabric will endure before it starts leaking. Generally speaking it is measured as a height of the water column of 1 inch diameter. Hydrostatic Head is a technical term of the pressure exerted by this column at the textile on the bottom end of the column.

All Gipfel tents’ rainflies (or the outer covers) have a resistance of at least 3,000 mm Hydrostatic Head. This is a excellent rain proofing for the tents and will not leak even under extremely heavy rain.

Gipfel tents’ ground sheets typically have a higher resistance to water than the rainflies, a minimum of 7,000 mm water resistance. This is for two reasons. One, there is a lot more pressure on the ground sheet from use which means the 3,000 mm water resistance is not adequate to avoid water seepage from the potentially damp ground, and two, this constant use also requires that the water proofing needs to be durable. Hence the 7,000 mm water resistance.

COATING ON INNER SIDE OF BASE FABRIC (WATER RESISTANT) / COATING ON OUTER SIDE (WATER REPELLENT)

There are typically two kinds of coating used mostly on tents – PU and Silicone.

Water Resistant PU Coating: This coating is applied in layers on the inner side of base fabric and provides water resistance. The thicker the layer, the more is the resistance to water penetration. This is always applied on the inner side of the textile and never on the outer side. The best thing about PU coating is that it enables the seams of the tent to be taped. This prevents the water from seeping through the needle holes in the seams. Because all Gipfel tents are seam taped in the factory, all tents have PU coating on the inner side of the base fabric.

The coatings can either just be water resistant or there may be specialty PU coatings within microscopic pores that provides breathability in addition to the water resistance. Such is the case with the Gipfel single walled KYRA tent.

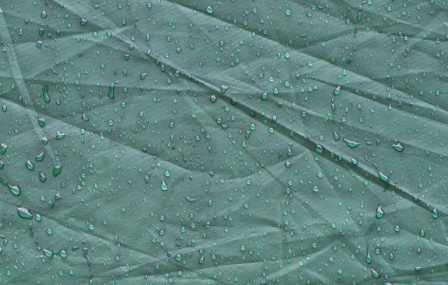

Water Repellent Silicone Coating: When applied on the outer side of base fabric, Silicone coating offers some UV resistance, better color fastness to UV, and most importantly, it is water repellent.

Water repellent coating prevents the textile from absorbing moisture / water. When water comes in contact with Silicone coating, it immediately beads up and drips off the surface without letting the base fabric from coming into contact with water.

If there is no information about the outer coating, then the tent probably has only the inner water resistant coating.

Gipfel rainflies have PU/Silicone. It means they have PU coatings on inner side and Silicone on outer side.

If you have any further questions, or feedback on this write up, please feel free to leave a note below, or mail us at info@gipfelclimbing.com.